The 400 series of regulators can be used in several different areas of application depending upon your requirements, with both single and dual stage regulator options, brass or stainless steel bar stock bodies, brass or chrome plated bonnets; but all with stainless steel diaphragms.

Below you can find links to the various specification sheets, with key attributes listed:

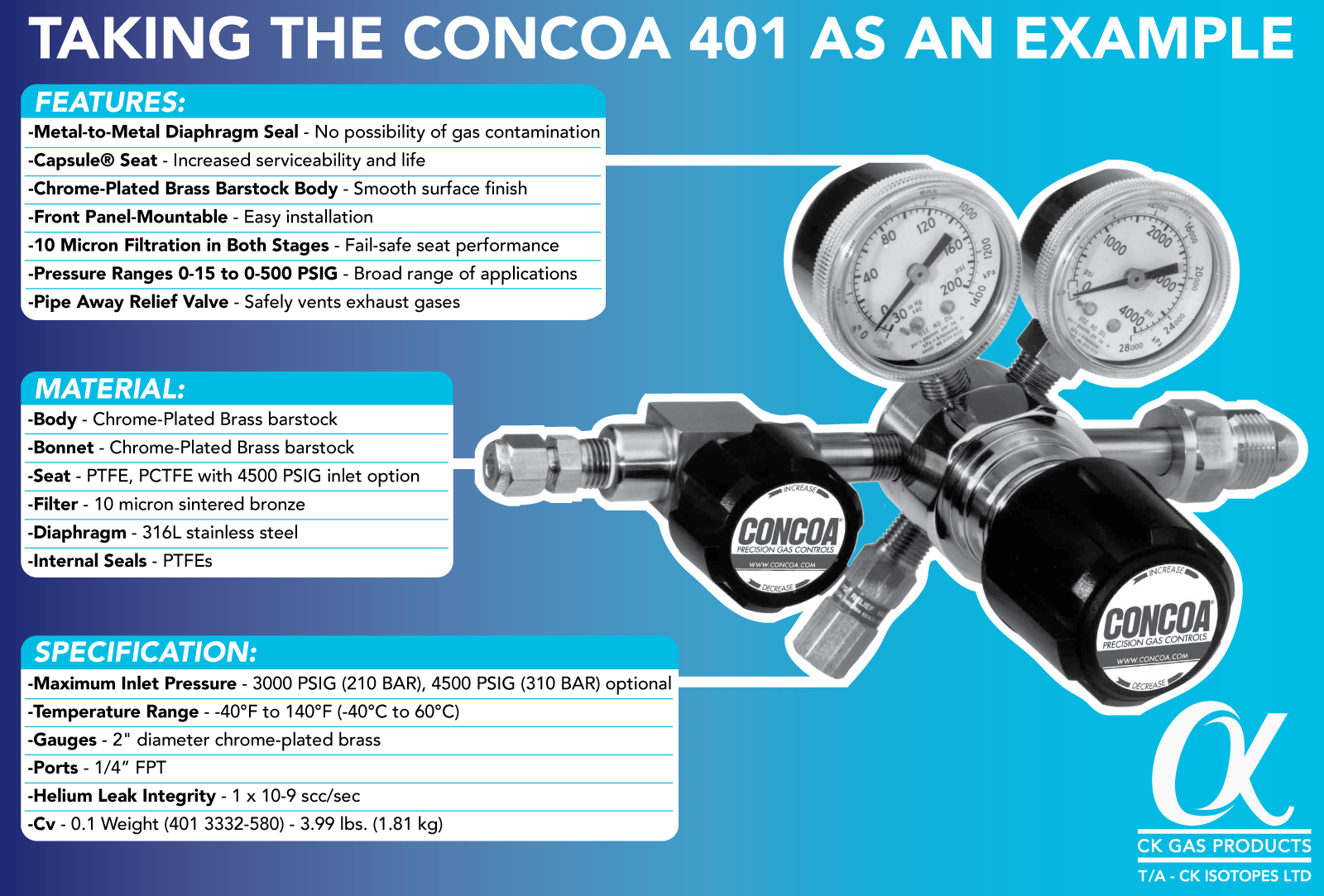

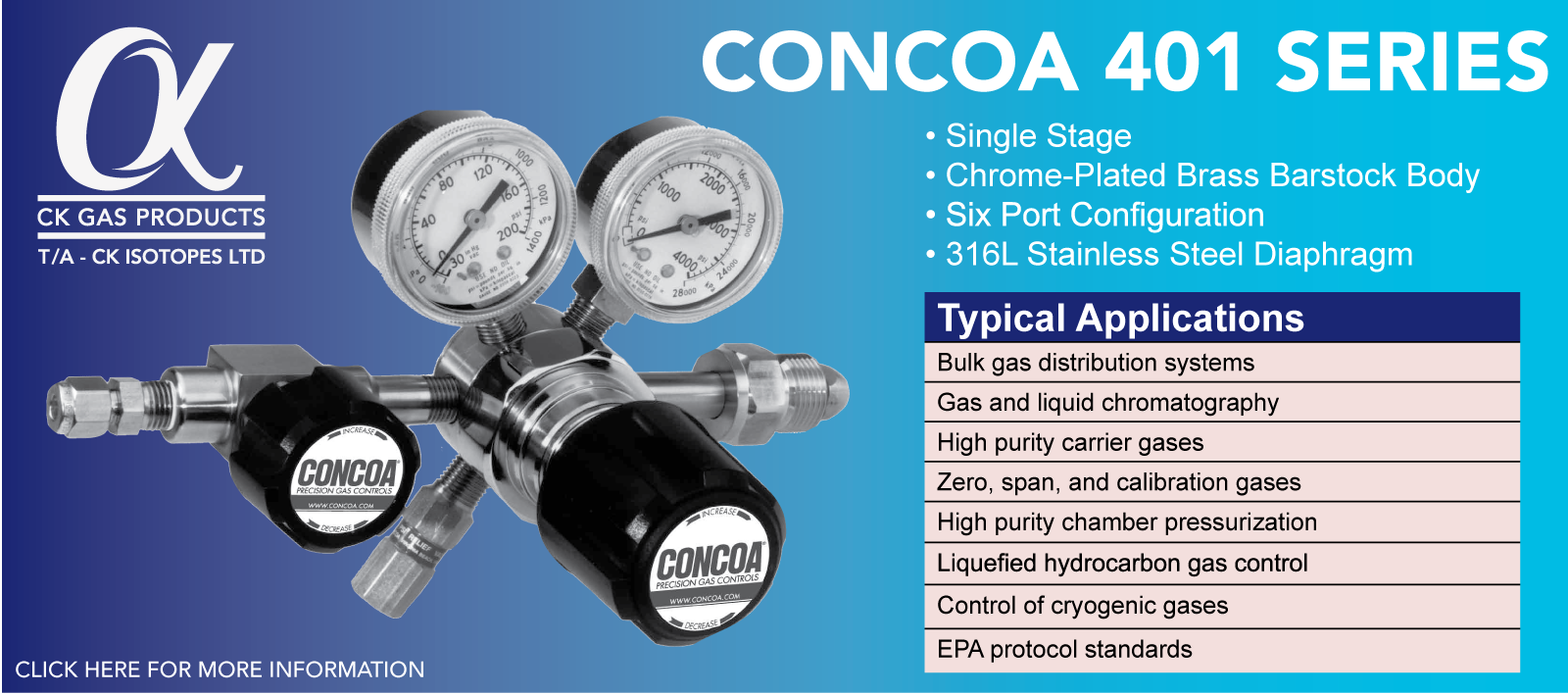

CONCOA 401 Regulator

The 401 Series regulators are intended for primary pressure control of non-corrosive, high purity or liquefied gases, or for applications where minor fluctuations in outlet pressure due to diminishing inlet supply can be tolerated.

401 Series Regulator with Flow Curve

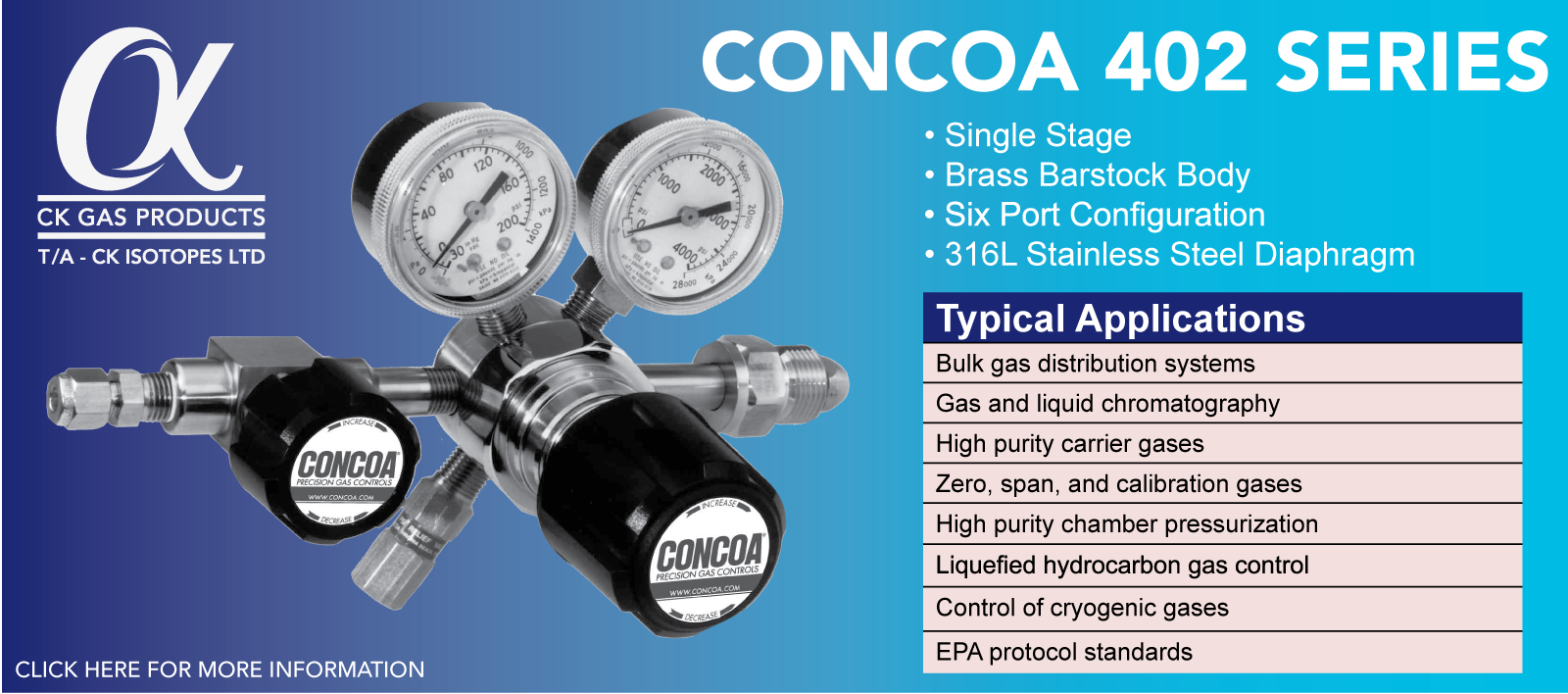

CONCOA 402 Regulator

The 402 Series regulators are intended for primary pressure control of non-corrosive, high purity or liquefied gases, or for applications where minor fluctuations in outlet pressure due to diminishing inlet supply can be tolerated.

402 Series Regulator with Flow Curve

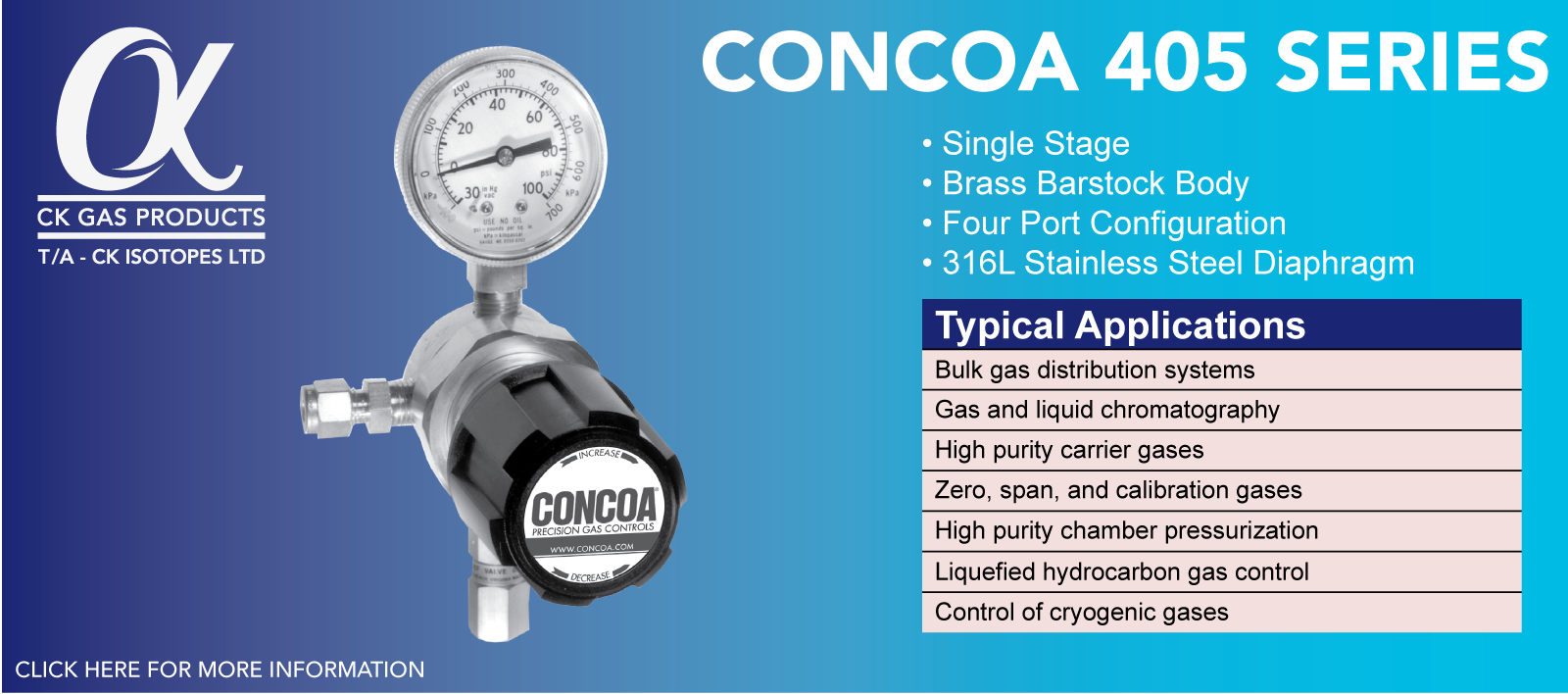

CONCOA 405 Regulator

Key Features – Single Stage, Brass Barstock Body, Four Port Configuration and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control and control of cryogenic gases.

405 Series Regulator with Flow Curve

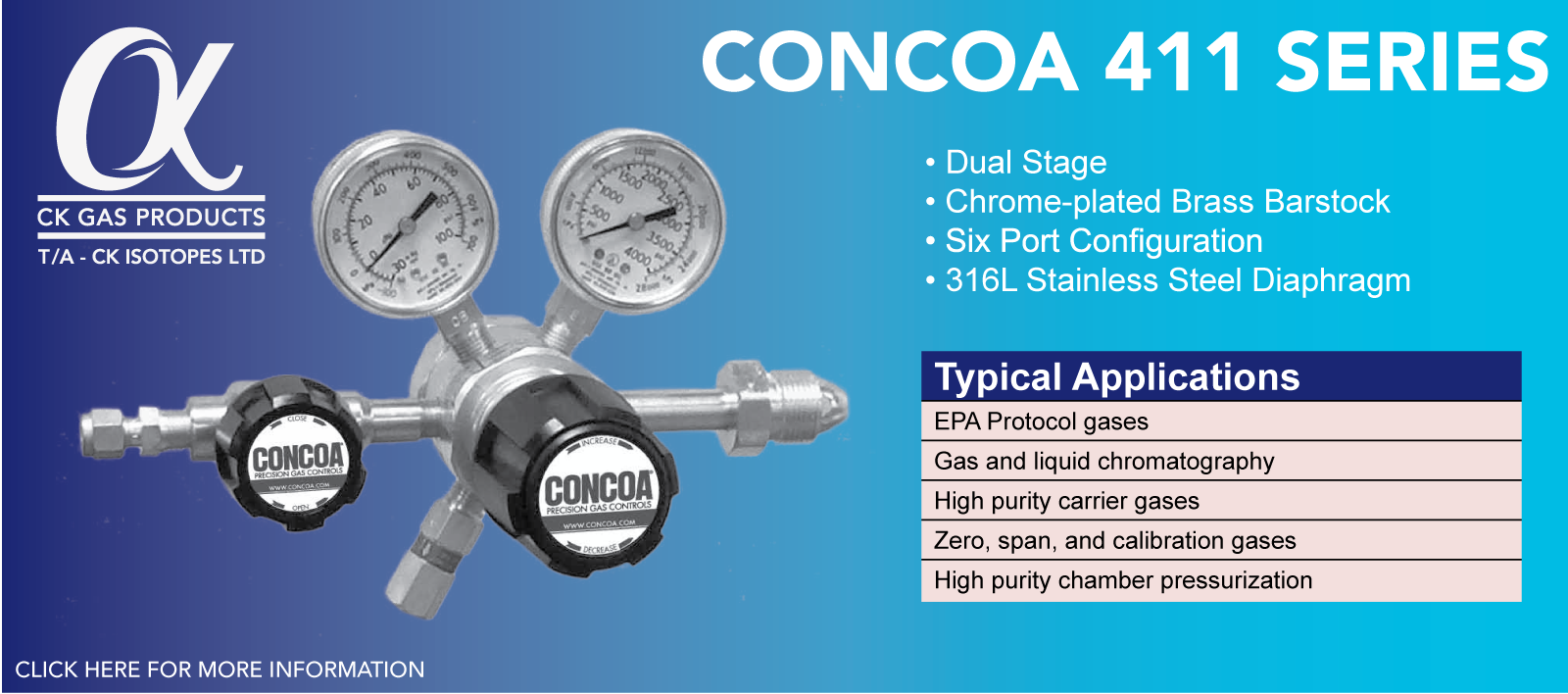

CONCOA 411 Regulator

The 411 Series regulators are intended for primary pressure control of non-corrosive, high purity or liquefied gases for applications requiring constant pressure control and delivery regardless of supply pressure variations.

411 Series Regulator with Flow Curve

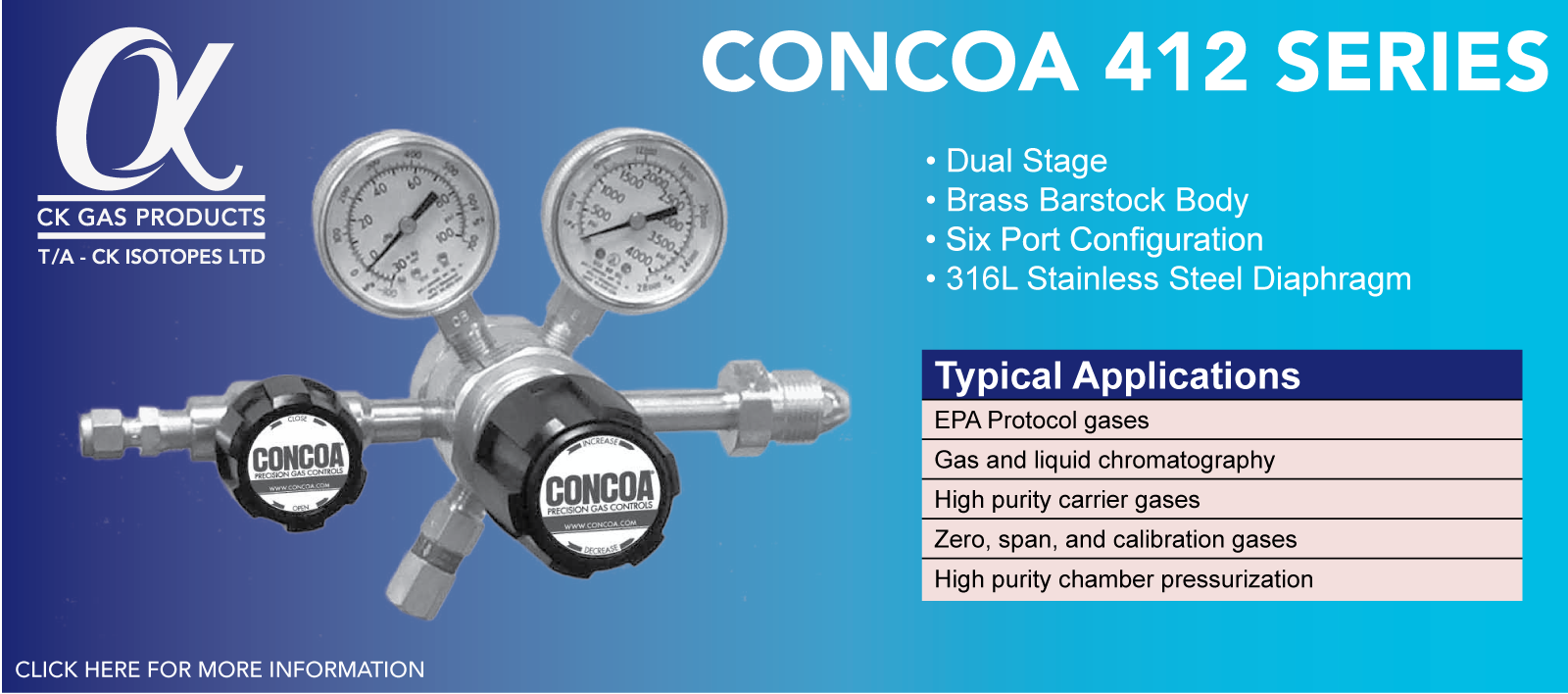

CONCOA 412 Regulator

The 412 Series regulators are intended for primary pressure control of non-corrosive, high purity or liquefied gases for applications requiring constant pressure control and delivery regardless of supply pressure variations.

412 Series Regulator with Flow Curve

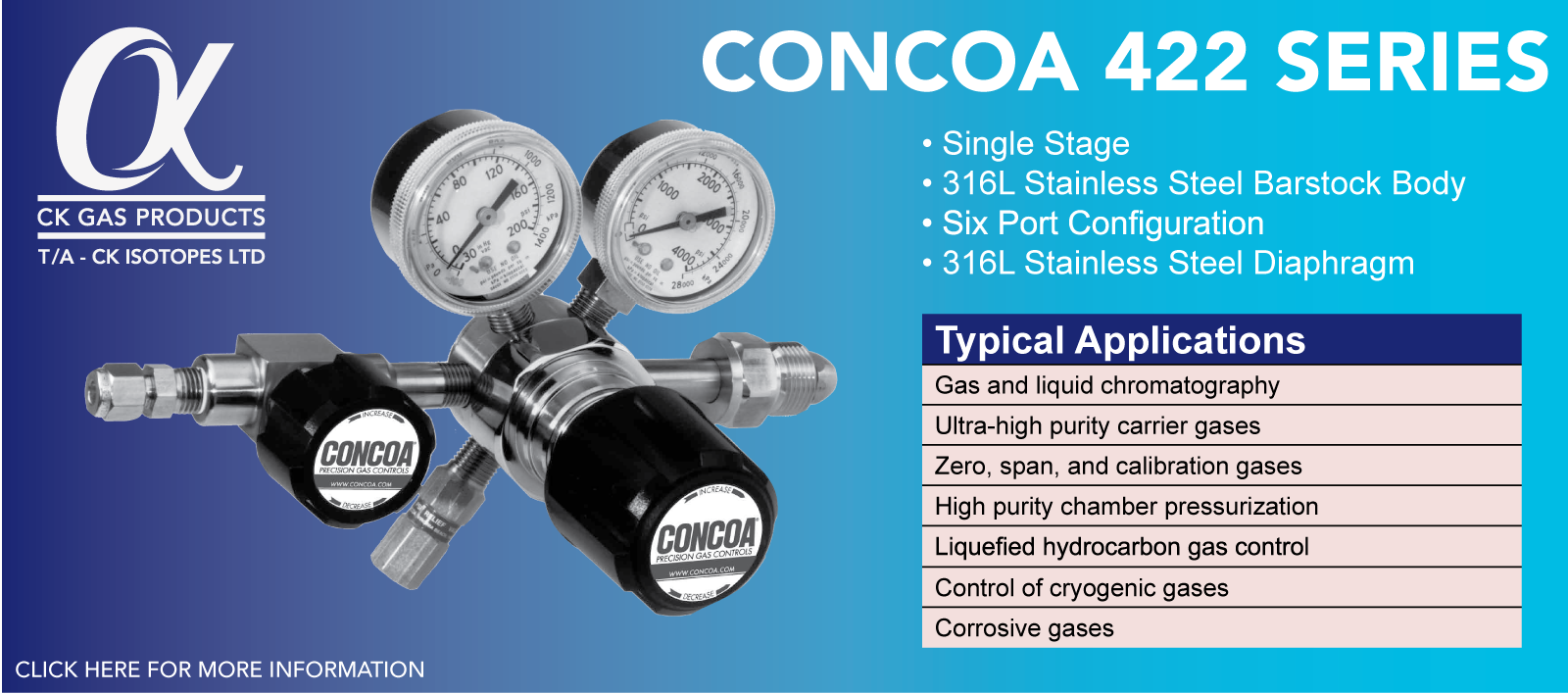

CONCOA 422 Regulator

The 422 Series regulators are intended for primary pressure control of ultra-high purity and corrosive gases in applications where minor fluctuations in outlet pressure due to diminishing inlet supply can be tolerated.

422 Series Regulator with Flow Curve

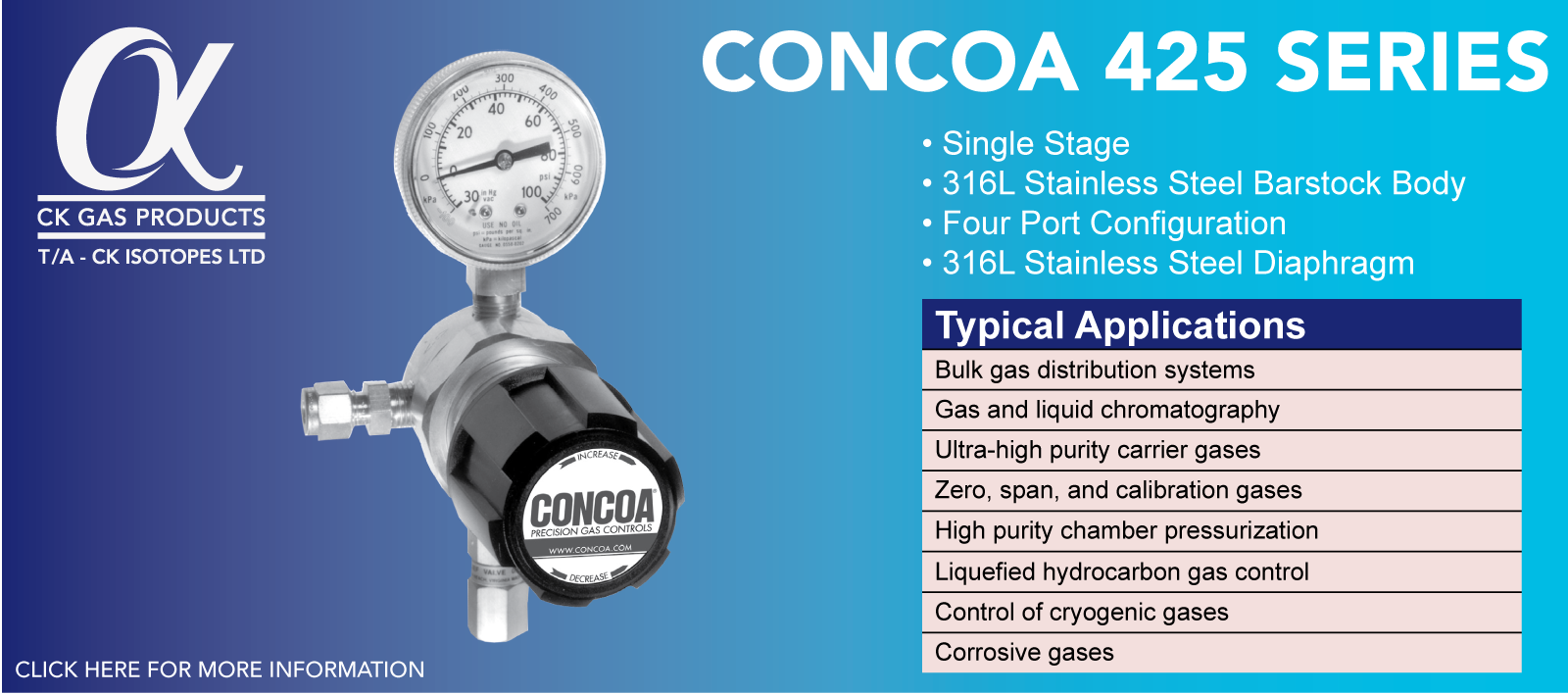

CONCOA 425 Regulator

Key Features – Single Stage, 316L Stainless Steel Barstock Body, Four Port Configuration and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, Ultra-high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control, control of cryogenic gases and corrosive gases.

425 Series Regulator with Flow Curve

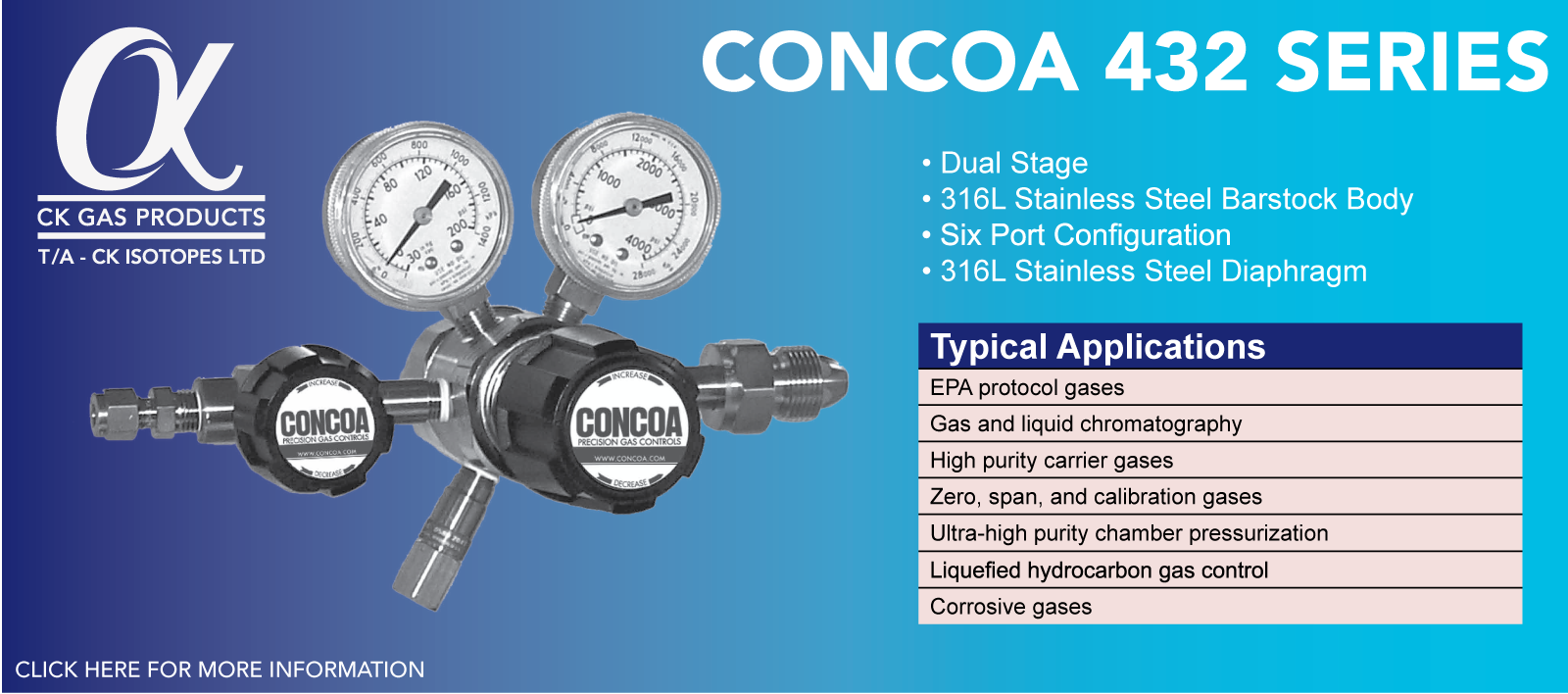

CONCOA 432 Regulator

The 432 Series regulators are intended for primary pressure control of ultra-high purity or corrosive gases for applications requiring constant pressure control and delivery regardless of supply pressure variations.

432 Series Regulator with Flow Curve

SEE BELOW FOR MORE CONCOA ULTRA-HIGH PURITY REGULATORS IN THE RANGE:

CONCOA 426 Regulator

Key Features – Low dead volume, 316L Stainless Steel Barstock Body, Two Port Configuration and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, Ultra-high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control, control of cryogenic gases and corrosive gases.

426 Series Regulator with Flow Curve

CONCOA 435 Regulator

Key Features – Single Stage, Rear Entry, Brass Barstock Body, Five Port Configuration and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control and control of cryogenic gases.

435 Series Regulator with Flow Curve

CONCOA 445 Regulator

Key Features – Single Stage, Rear Entry, 316L Stainless Steel Barstock Body, Five Port Configuration and 316L Stainless Steel Diaphragm.

Typical Applications – Bulk gas distribution systems, gas and liquid chromatography, Ultra-high purity carrier gases, zero / span / calibration gases, high purity chamber pressurisation, liquefied hydrocarbon gas control, control of cryogenic gases and Corrosive service.

445 Series Regulator with Flow Curve

Please contact us for a quote or if you have any questions.

TAKING THE 402 REGULATOR AS AN EXAMPLE

Features:

Metal-to-Metal Diaphragm Seal – No possibility of gas contamination

Capsule® Seat – Increased serviceability and life

Brass Barstock Body – Smooth surface finish

Front Panel-Mountable – Easy installation

10 Micron Filtration in Both Stages – Fail-safe seat performance

Pressure Ranges 0-15 to 0-250 PSIG – Broad range of applications

Pipe Away Relief Valve – Safely vents exhaust gases

Material:

Body – Brass barstock

Bonnet – Brass barstock

Seat – PTFE, PCTFE with 4500 PSIG inlet option

Filter – 10 micron sintered bronze

Diaphragm – 316L stainless steel

Internal Seals – PTFE

Specification:

Maximum Inlet Pressure – 3000 PSIG (210 BAR), 4500 PSIG (310 BAR) optional

Temperature Range – -40°F to 140°F (-40°C to 60°C)

Gauges – 2″ diameter brass

Ports – 1/4” FPT

Helium Leak Integrity – 1 x 10-9 scc/sec

Cv – 0.1 Weight (402 2331-580) – 3.99 lbs. (1.81 kg)

Regulators – ULTRA HIGH PURITY

Product Search

Got a Question?

For information please start your enquiry below: