The 400 Series SilcoNert 1020 coated regulators are intended for primary pressure control of reactive or corrosive calibration mixtures or pure gases in applications where an extreme inert wetted finish is required. The proprietary non-reactive amorphous silicon finish is desired over standard 316L stainless steel and ideally suited for H2S, reduced sulphur, mercury and PPM to PPB calibration mixtures.

The 400 Series SilcoNert 1020 coated regulators are intended for primary pressure control of reactive or corrosive calibration mixtures or pure gases in applications where an extreme inert wetted finish is required. The proprietary non-reactive amorphous silicon finish is desired over standard 316L stainless steel and ideally suited for H2S, reduced sulphur, mercury and PPM to PPB calibration mixtures.

Below you can find links to the various specification sheets, with key attributes listed:

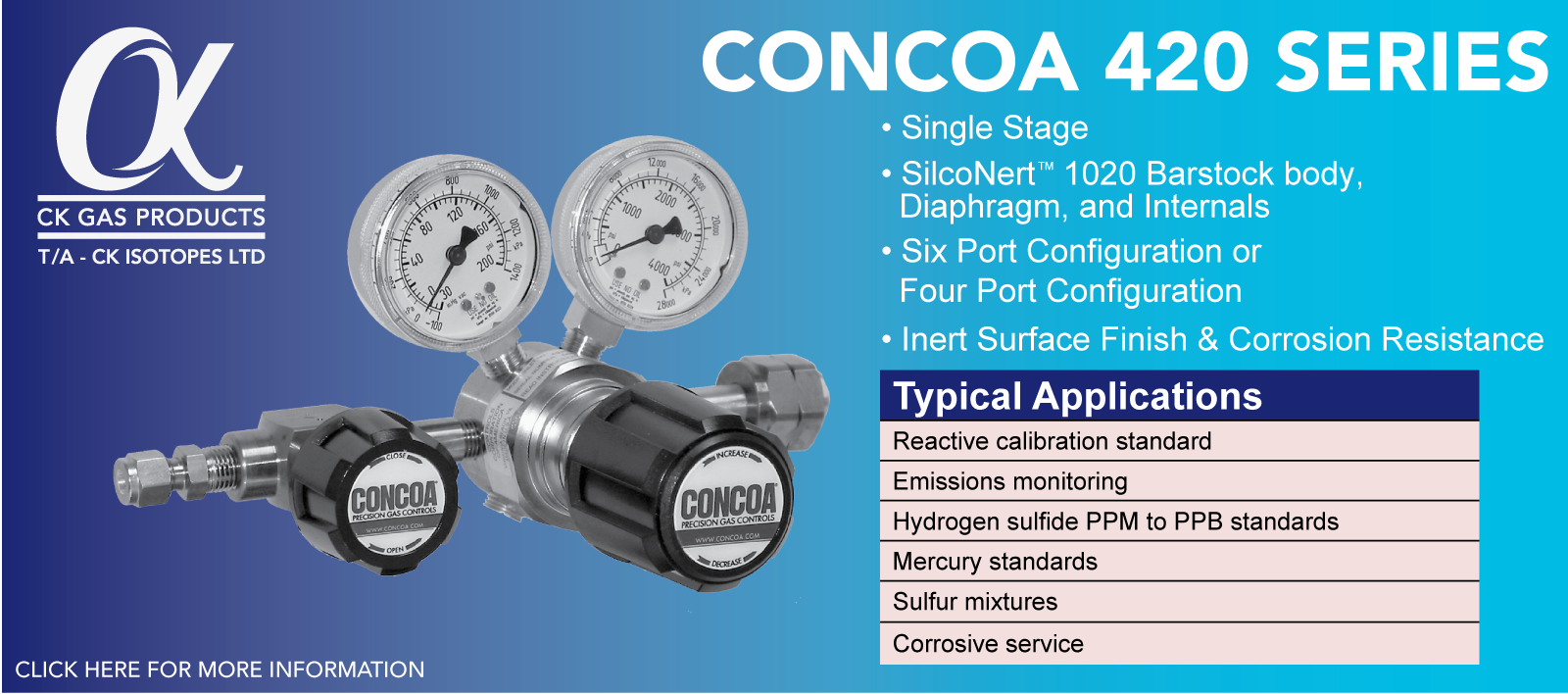

CONCOA 420 Regulator

420 Series Regulator with Flow Curve

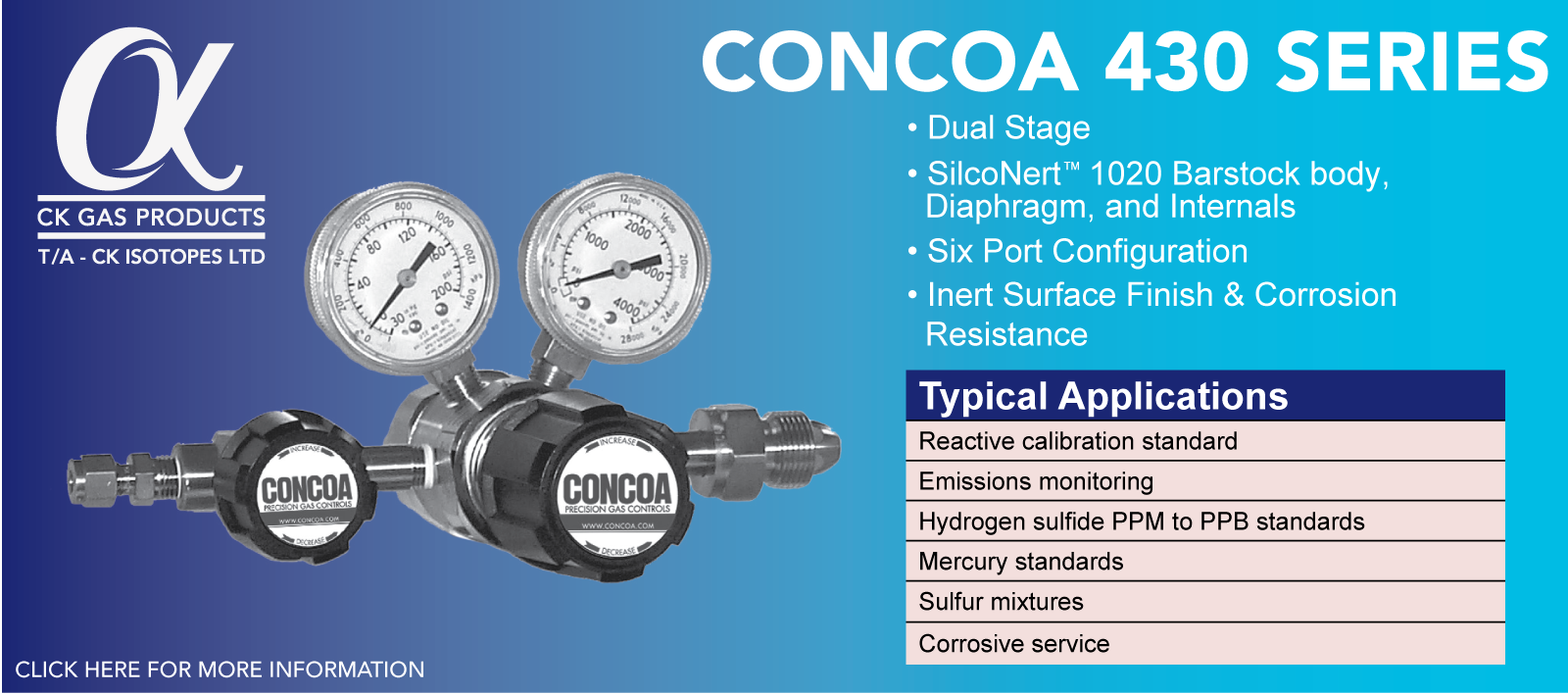

430 Series Regulator with Flow Curve

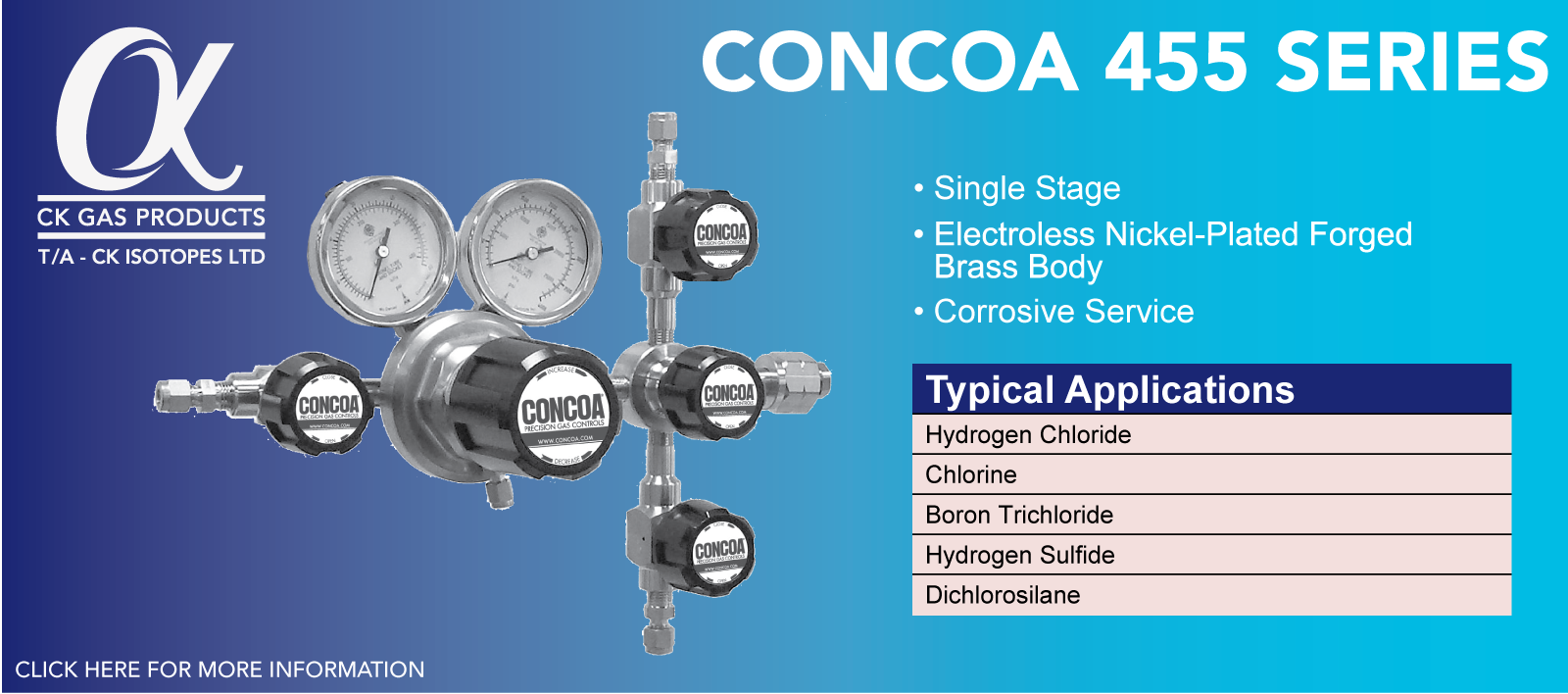

CONCOA 455 Regulator

455 Series Regulator with Flow Curve

Please contact us for a quote or if you have any questions.

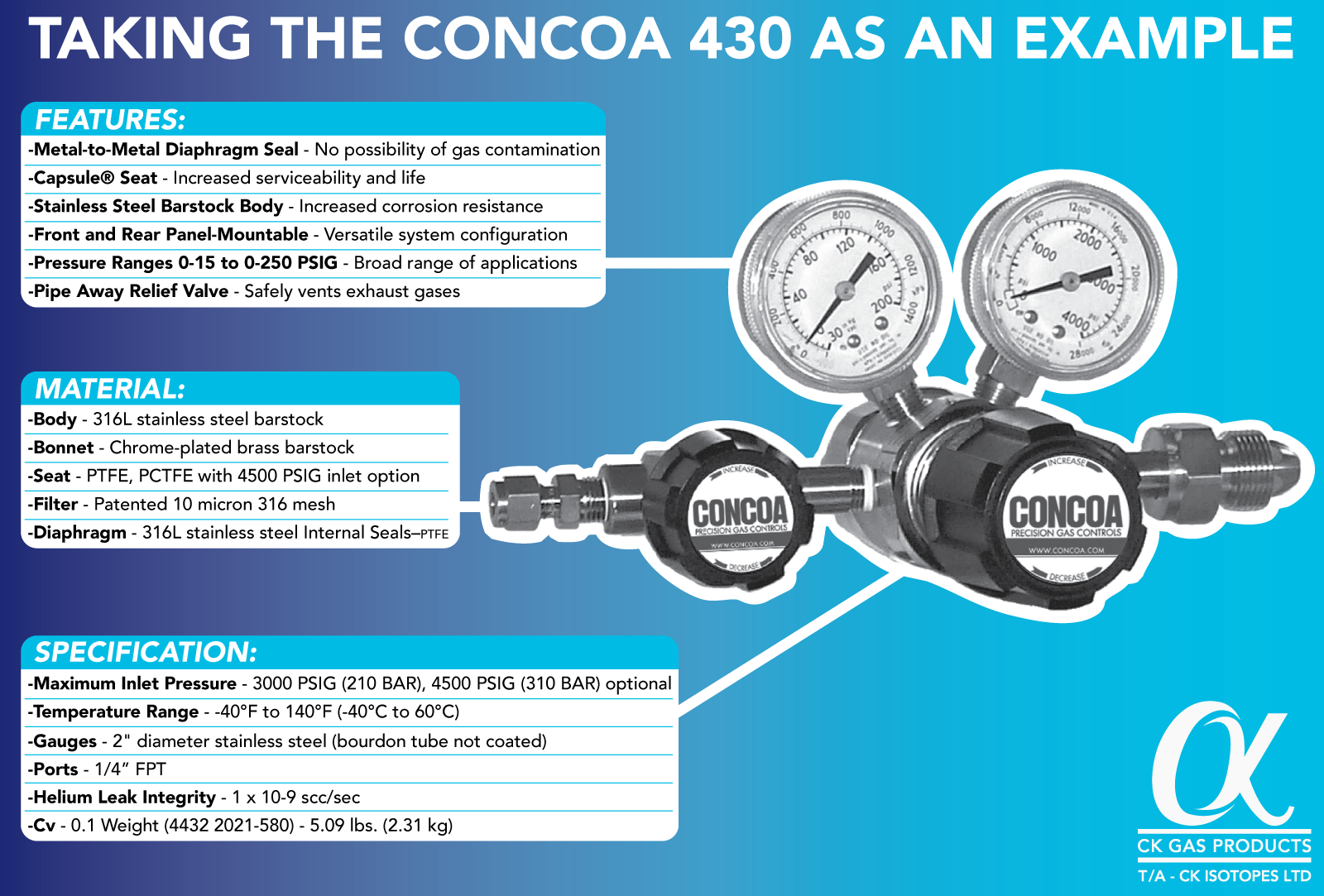

Snapshot of the 430 SilcoNert

The 430 Series SilcoNert 1020 coated regulators are intended for pressure control of reactive or corrosive calibration mixtures or pure gases in applications where an extreme inert wetted finish is required along with stable delivery pressure regardless of inlet pressure. The proprietary non-reactive amorphous Silicon finish is desired over standard 316L stainless steel and ideally suited for H2S, reduced Sulfur, Mercury and PPM to PPB calibration mixtures.

430 Series SilcoNert Regulator

Key Features

• Dual Stage

• SilcoNert™ 1020 Coated Body, Diaphragm, and Internals

• 316L stainless steel Barstock Body

• Six Port Confi guration

• Inert Surface Finish and Corrosion Resistance

Typical Applications

• Reactive calibration standard

• Emissions monitoring

• H2S PPM to PPB standards

• Mercury standards

• Sulfur mixtures

• Corrosive gases

Features

Metal-to-Metal Diaphragm Seal – No possibility of gas contamination

Capsule® Seat – Increased serviceability and life

Stainless Steel Barstock Body – Increased corrosion resistance

Front and Rear Panel-Mountable – Versatile system configuration

Pressure Ranges 0-15 to 0-500 PSIG – Broad range of applications

Pipe Away Relief Valve – Safely vents exhaust gases

Materials

Body – 316L stainless steel barstock

Bonnet – Chrome-plated brass barstock

Seat – PTFE, PCTFE with 4500 PSIG inlet option

Filter – Patented 10 micron 316 mesh

Diaphragm – 316L stainless steel Internal Seals – PTFE

Specifications

Maximum Inlet Pressure – 3000 PSIG (210 BAR), 4500 PSIG (310 BAR) optional

Temperature Range – -40°F to 140°F (-40°C to 60°C)

Gauges – 2″ diameter stainless steel (bourdon tube not coated)

Ports – 1/4” FPT

Helium Leak Integrity – 1 x 10-9 scc/sec

Cv – 0.1 Weight (432 2021-580) – 5.09 lbs. (2.31 kg)

Regulators – CORROSIVE AND TOXIC

Product Search

Got a Question?

For information please start your enquiry below: